INDUSTRY NEWS

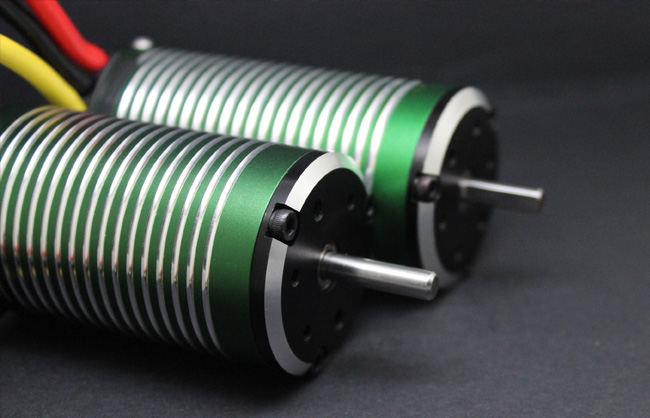

Brushless motor Getting Started

One: The definition of brushless motor:

Abbreviation for brushless motor, it is divided into two types: one is the inner rotor brushless motor, and the other is the outer rotor brushless motor. The corresponding product is called carbon brush motor.

Two: The difference between brushless motor and carbon brush motor:

1: Generally speaking, the heat dissipation of brushless motors is better than that of carbon brushes, especially for outer rotors.

2: The power efficiency of the brushless is relatively high, and part of the carbon brush will be consumed on the frictional heat energy of the brush, so it will be relatively low.

3: If it is under the premise of normal use (no high temperature, no overload, no external force impact, etc.), the brushless motor does not have the problem of carbon brush wear, it can be said that it has no service life limit.

4: The wear rate of brushless motors is much larger than that of brushless motors, and some are even hundreds of times different. Especially when the same is used on a high-speed aircraft, the difference is particularly obvious. From this perspective, as long as the brushless motor does not fall to the Compared with the service life and performance, coupled with the price factor, it is much more beneficial than the carbon brush motor.

5: Power decline is a common problem with carbon brushes; but there is no such problem for brushless.

6: The carbon brush needs to clean the carbon powder regularly and run-in; but no brush has no such problem.

7: Under the same output power, the weight of brushless will be lighter than that of carbon brush.

8: Because the carbon brush is restricted by the brush spring bracket, there is a problem of bouncing, so the speed of the brushless will be faster than that of the carbon brush.

Three: Definition of inner rotor brushless motor and outer rotor brushless motor:

1: Inner rotor brushless motor: refers to the motor shaft will rotate, the coil is in the motor shell, and the magnet is on the shaft.

2: Outer rotor brushless motor; means that the motor shell will rotate, the coil is on the axis, and the magnet is on the shell.

Four: The advantages of the inner rotor brushless motor and the outer rotor brushless motor:

1: The advantages of the inner rotor brushless motor: Generally speaking, because of its smaller diameter, it is more conducive to the exertion of high-speed torque.

2: The advantages of the outer rotor brushless motor: it has better heat dissipation and a larger diameter, which is more conducive to low-speed torque.

Five: the advantages of brushless motors:

1: Brushless efficiency:

Under the same current, the power increases, the flight time is longer, the torque and speed of the brushless are generally better than that of the carbon brush, and the power consumption is also less. Therefore, the use of the brushless is the same whether it is slow flying or fast flying. The battery will stay in the air for a longer time.

2. Brushless function:

Fast-flying airplanes require greater pull and thrust, and it is better to use a brushless motor, which makes it more satisfying to fly.

Six: What is KV value:

KV=PRM/V=speed per volt, which refers to the speed of the motor. Motors with different KV values have different internal resistance and current when idling, so the power consumption will be different.

High KV value, can be matched with various deceleration groups to meet the requirements;

The brushless motor with low KV value is used for direct drive.

The inner rotor brushless KV value is relatively high, which is suitable for the reducer, and the low voltage can exert better efficiency;

The brushless KV value of the outer rotor is relatively low, which is suitable for playing with a 3D machine to directly drive a large propeller.

Seven: How to calculate the actual KV value:

1: Use the KV value of about 70℅ when there is a load speed, you can know how big the proper propeller is.

2: Find a piece of thin and light material to make the light-shielding film, and cut it into the following figure, the diameter is slightly larger than the motor shell, measure the current voltage and speed, and then divide the speed by the load voltage, which is the KV value of the motor.

eg:

The measured speed is: 28000RPM; the load voltage is: 12.3V (the voltage measured when the motor is rotating)

That is, KV=28000RPM/12.3V=2276KV.

Eight: Brushless forward and reverse problems:

There are three wires on the brushless motor, and you can change the forward and reverse rotation by simply replacing two of them. Usually, the two sides are not changed in the middle.

Nine: What is the idling speed:

It refers to the motor speed per 1 volt under no load conditions (without propellers).

Ten: Why the energy conversion efficiency of brushless is higher than that of carbon brush:

Because with the same battery capacity and the same motor kinetic energy output, brushless can output longer than carbon brushes (that is, fly longer) eg:

Use 370 deceleration group; use 7.5*5 propeller; use 7.4V2300mAh lithium battery; full speed is about 8A; the motor is very hot when flying, and the flight time is about 15 minutes.

Use outer rotor brushless 400T; direct drive 7.5*5 propeller; use 7.4V2300mAh lithium battery; full speed is about 8A; flying down the motor is warm, the flight time is about 20 minutes.

Eleven: What does 3S2P stand for:

It refers to three series and two parallel, that is, the voltage is increased by 3 times (motor revolutions), the capacity is increased by 2 times (operation time), and the weight is increased by 6 times. eg:

If there are six batteries for 3.7V1000mAh:

When the batteries are connected in series: the code is S, 3S means that 3 batteries are connected in series, the voltage is 3.7+3.7+3.7=11.1V; the capacity is 1000mAh unchanged; the motor speed is tripled, and the running time is unchanged.

When the batteries are connected in parallel: the code is P, 2P means that two batteries are connected in parallel, the voltage remains unchanged at 3.7V; the capacity increases by 1000+1000=2000mAh; the motor speed remains unchanged, and the running time is doubled.

☆ Formula: series voltage addition, parallel current and capacity addition.

Twelve: What are 130, 280, 370, 540, 2030, 2040 motors:

These numbers indicate the specifications and models of the motors.

Generally, numbers like 130, 280, 370, and 540 represent the specifications and models of the carbon brush motor, and represent the length of the motor. Generally speaking, the longer the motor, the greater the power.

Brushless motors generally use diameter and length to be nominal at the same time, such as: 2030: that is, the diameter of the motor is 20mm, and the length is 30mm. (The diameter is in the front and the length is in the back when nominal).

Of course, there are also brushless motors that use 130. 280, 540 are nominal, but this has nothing to do with the size of the motor, nor can it be equivalent to the specifications of a carbon brush motor.

Abbreviation for brushless motor, it is divided into two types: one is the inner rotor brushless motor, and the other is the outer rotor brushless motor. The corresponding product is called carbon brush motor.

Two: The difference between brushless motor and carbon brush motor:

1: Generally speaking, the heat dissipation of brushless motors is better than that of carbon brushes, especially for outer rotors.

2: The power efficiency of the brushless is relatively high, and part of the carbon brush will be consumed on the frictional heat energy of the brush, so it will be relatively low.

3: If it is under the premise of normal use (no high temperature, no overload, no external force impact, etc.), the brushless motor does not have the problem of carbon brush wear, it can be said that it has no service life limit.

4: The wear rate of brushless motors is much larger than that of brushless motors, and some are even hundreds of times different. Especially when the same is used on a high-speed aircraft, the difference is particularly obvious. From this perspective, as long as the brushless motor does not fall to the Compared with the service life and performance, coupled with the price factor, it is much more beneficial than the carbon brush motor.

5: Power decline is a common problem with carbon brushes; but there is no such problem for brushless.

6: The carbon brush needs to clean the carbon powder regularly and run-in; but no brush has no such problem.

7: Under the same output power, the weight of brushless will be lighter than that of carbon brush.

8: Because the carbon brush is restricted by the brush spring bracket, there is a problem of bouncing, so the speed of the brushless will be faster than that of the carbon brush.

Three: Definition of inner rotor brushless motor and outer rotor brushless motor:

1: Inner rotor brushless motor: refers to the motor shaft will rotate, the coil is in the motor shell, and the magnet is on the shaft.

2: Outer rotor brushless motor; means that the motor shell will rotate, the coil is on the axis, and the magnet is on the shell.

Four: The advantages of the inner rotor brushless motor and the outer rotor brushless motor:

1: The advantages of the inner rotor brushless motor: Generally speaking, because of its smaller diameter, it is more conducive to the exertion of high-speed torque.

2: The advantages of the outer rotor brushless motor: it has better heat dissipation and a larger diameter, which is more conducive to low-speed torque.

Five: the advantages of brushless motors:

1: Brushless efficiency:

Under the same current, the power increases, the flight time is longer, the torque and speed of the brushless are generally better than that of the carbon brush, and the power consumption is also less. Therefore, the use of the brushless is the same whether it is slow flying or fast flying. The battery will stay in the air for a longer time.

2. Brushless function:

Fast-flying airplanes require greater pull and thrust, and it is better to use a brushless motor, which makes it more satisfying to fly.

Six: What is KV value:

KV=PRM/V=speed per volt, which refers to the speed of the motor. Motors with different KV values have different internal resistance and current when idling, so the power consumption will be different.

High KV value, can be matched with various deceleration groups to meet the requirements;

The brushless motor with low KV value is used for direct drive.

The inner rotor brushless KV value is relatively high, which is suitable for the reducer, and the low voltage can exert better efficiency;

The brushless KV value of the outer rotor is relatively low, which is suitable for playing with a 3D machine to directly drive a large propeller.

Seven: How to calculate the actual KV value:

1: Use the KV value of about 70℅ when there is a load speed, you can know how big the proper propeller is.

2: Find a piece of thin and light material to make the light-shielding film, and cut it into the following figure, the diameter is slightly larger than the motor shell, measure the current voltage and speed, and then divide the speed by the load voltage, which is the KV value of the motor.

eg:

The measured speed is: 28000RPM; the load voltage is: 12.3V (the voltage measured when the motor is rotating)

That is, KV=28000RPM/12.3V=2276KV.

Eight: Brushless forward and reverse problems:

There are three wires on the brushless motor, and you can change the forward and reverse rotation by simply replacing two of them. Usually, the two sides are not changed in the middle.

Nine: What is the idling speed:

It refers to the motor speed per 1 volt under no load conditions (without propellers).

Ten: Why the energy conversion efficiency of brushless is higher than that of carbon brush:

Because with the same battery capacity and the same motor kinetic energy output, brushless can output longer than carbon brushes (that is, fly longer) eg:

Use 370 deceleration group; use 7.5*5 propeller; use 7.4V2300mAh lithium battery; full speed is about 8A; the motor is very hot when flying, and the flight time is about 15 minutes.

Use outer rotor brushless 400T; direct drive 7.5*5 propeller; use 7.4V2300mAh lithium battery; full speed is about 8A; flying down the motor is warm, the flight time is about 20 minutes.

Eleven: What does 3S2P stand for:

It refers to three series and two parallel, that is, the voltage is increased by 3 times (motor revolutions), the capacity is increased by 2 times (operation time), and the weight is increased by 6 times. eg:

If there are six batteries for 3.7V1000mAh:

When the batteries are connected in series: the code is S, 3S means that 3 batteries are connected in series, the voltage is 3.7+3.7+3.7=11.1V; the capacity is 1000mAh unchanged; the motor speed is tripled, and the running time is unchanged.

When the batteries are connected in parallel: the code is P, 2P means that two batteries are connected in parallel, the voltage remains unchanged at 3.7V; the capacity increases by 1000+1000=2000mAh; the motor speed remains unchanged, and the running time is doubled.

☆ Formula: series voltage addition, parallel current and capacity addition.

Twelve: What are 130, 280, 370, 540, 2030, 2040 motors:

These numbers indicate the specifications and models of the motors.

Generally, numbers like 130, 280, 370, and 540 represent the specifications and models of the carbon brush motor, and represent the length of the motor. Generally speaking, the longer the motor, the greater the power.

Brushless motors generally use diameter and length to be nominal at the same time, such as: 2030: that is, the diameter of the motor is 20mm, and the length is 30mm. (The diameter is in the front and the length is in the back when nominal).

Of course, there are also brushless motors that use 130. 280, 540 are nominal, but this has nothing to do with the size of the motor, nor can it be equivalent to the specifications of a carbon brush motor.