INDUSTRY NEWS

Thrusters/Propellers/Propulsion

Propellers (Propellers) are devices that convert any form of energy into mechanical energy. Thrust is generated by rotating blades or jets of air (water). It can be used to drive a vehicle forward or as a source of power for other devices such as generators.

Early developments

The principle employed in the use of propellers was that used in rowing boats. This was a part of the development of propulsion in Venice, but in Europe and elsewhere it was probably used in other ways. For example, propelling a canoe using a single paddle or sliding a canoe sideways with a 'scull' involved similar techniques. In China, the paddle known as the 'lu' was also used in the 3rd century AD.

In a rowing line, a single blade moves from side to side through an arc, taking care to keep the blade presented to the water at an effective angle. An innovation introduced with the propeller was the extension of the arc beyond 360° by attaching the blades to the axis of rotation. Propellers can have a single blade, but in practice there is almost always more than one, in order to balance the forces involved.

The origins of the propeller began to be associated with Archimedes, who used a screw to lift water for irrigation and salvage boats, so famously that it became known as the Archimedean screw pump. It is possible that the spiral motion in space (the spiral was specifically studied for application by Archimedes) was used to irrigate hollow segmented waterwheels by the Egyptians for centuries. Leonardo da Vinci adopted this principle to drive his theoretical helicopter, the sketch of which involved a large canvas screw head.

In 1784, JP Paucton proposed the use of two lifts and propulsion for a similar screw-rotor aircraft. At about the same time, James Watt used screws to propel ships, but he did not propose them for use in his steam engines. It was not his own invention; Toogood and Hays had patented it a century earlier, and since then it has become a common means of propelling ships.

By 1827, the Czech and Austrian inventor Josef Ressel had invented the propeller which had multiple blades fixed around a conical base. He tested his propeller in February 1826 on a small, manually driven boat. He successfully used his bronze propeller in an adapted steamboat (1829). His ship "Civetta Hill" with 48 gross register tons, reached a speed of about 6 knots (11 km/h). This was the first ship propelled by an Archimedean propeller. After an accident with a new steam engine (cracked pipe welding), his experiments were banned by the Austro-Hungarian police as dangerous. Before that, however, he received an Austro-Hungarian patent (licence) for his propeller (1827). He died in 1857. This new method of propulsion was an improvement on the water wheel as it was not affected by the movement of the ship or by changes in the draught of the ship burning coal.

John Patch, a sailor in Yarmouth, Nova Scotia, formulated a two-bladed, flapping propeller in 1832 and publicly demonstrated it in 1833, propelling the ship across the Port Row in Yarmouth and in the small coastal sailing ship St. John's, New Brunswick, but his application for a patent in the United States was rejected until 1849 because he was not a US citizen. His efficient design attracted critical acclaim in the American scientific community but by this time there were multiple competing versions of the ship's propeller.

The propeller

Although there were many experiments with screw propulsion before the 1930s, few of these inventions were pushed to the testing stage and those that were proved unsatisfactory for one reason or another.

Two full turns of Smith's patented 1836 propeller. He later amended the patent to reduce the length to one revolution.

In 1835, in England, two inventors, John Ericsson and Francis Pettitt Smith, began to work separately on the problem. Smith was the first to come up with a patent for a propeller on 31 May, while Ericsson, a talented Swedish engineer, then working in England, presented his patent six weeks later. Smith soon built a small model boat to test his invention, which he first showed on Pond Hendon Farm and later at the Royal Gallery of Practical Science in Adelaide London, where it was seen by the Secretary of the Navy, Sir William Barrow. Secured though the patronage of a London banker named Wright, Smith then built a 30 foot, six horsepower is six ton canal boat annoyingly dry called Francis Smith, which was fitted with a wooden propeller of his own design and displayed on the Paddington Canal from November 1836 to September 1837. Due to a fortuitous accident, the two-turn wooden propeller was damaged during the voyage in February 1837, and to Smith's amazement the broken propeller, which included only one turn, went from about four miles an hour to eight. Smith would subsequently submit an amended patent on this unexpected discovery.

In the meantime, Ericsson built a 45-foot screw-propelled ship, Francis B. Ogden in 1837, and showed him on board the Thames to senior members of the British Navy, including Mr. William Symonds, a surveyor in the United States Navy. Although the ship achieved a speed of 10 miles per hour, with the existing comparable speed of the Mineliner, Simonds and his entourage were unimpressed. The Admiralty considered screw propulsion to be ineffective in sea navigation, and Symonds himself believed that propeller propelled boats could not be manoeuvred effectively. After this rejection, Ericsson built a second larger screw-propelled ship, Robert Stockton, and had her sailed to America in 1839, where he soon gained fame as the designer of the U.S. Navy's "first screw-propelled warship, USS Princeton.

Apparently the Navy thought that the propeller would prove unsuitable for sea service and Smith was determined to prove this assumption wrong. In September 1837 he took the Small Vessel (now equipped with a single-turn iron propeller) to sea, steaming from Blackwall, London to Hayes, Kent, with stops at Ramsgate, Dover and Folkestone. On the way back to London on the 25th, Smith's craft was observed making progress in stormy seas by Royal Navy officials. Admiralty interest in the technology was revived and Smith was encouraged to build a full-size ship to demonstrate more conclusively the effectiveness of the technology.

SS Archimedes was built in 1838 by Henry Wimshurst of London and became the world's first ship to be driven by a propeller

Archimedes had considerable influence on the development of ships, encouraging the adoption of the screw propeller by the Royal Navy, in addition to her influence on the merchant marine. The trial of SS Archimedes with Smith led to the famous tug-of-war competition between the screw drive in 1845 between HMS Rattlesnake and the Ming ship HMS Alekto; the former pulled backwards at 2.5 knots (4.6km/h).

She also had a direct influence on the design of another innovative vessel, Isambard Kindem Brunel's Great Britain, then the world's largest ship and the first screw-propelled liner to cross the Atlantic, in 1845 with a propeller design stabilised in the 1880s.

Aircraft propulsion

The twisted wing shape of modern aircraft propellers was pioneered by the Wright brothers. Although some earlier engineers had attempted to model the air propeller on a marine propeller, the Wright brothers realised that the propeller was essentially the same as the wing and were able to use data on the wing from their earlier wind tunnel experiments. They also introduced a twist along the length of the blades. This was necessary to ensure that the angle of attack of the blade remained relatively constant along its length. Their original propeller blades were only about 5% less efficient than the equivalent modern ones, some 100 years later. The understanding of low-speed propeller aerodynamics was fairly complete by the 1920s, but the later requirement for smaller diameters to handle more power has made the problem more complex.

Alberto Santos Dumont, another early pioneer, applied the experience he gained from working with dirigibles to make a biplane with a steel shaft and aluminium blades for his propeller two of 14. Some of his designs used bent aluminium plates for the blades, thus producing the wing shape. They were heavy undercambered and this coupled with the lack of longitudinal twist made them less efficient than the Wright propellers. Even so, this was probably the first use of aluminium in the construction of a propeller.

Main types

Propeller propellers are referred to as propellers. The propeller is mounted on the propeller shaft below the waterline at the stern of the boat and is driven by the main engine to rotate the propeller shaft together, drawing water in from the intake side of the propeller blade and discharging it from the discharge side, using the reaction force of the water to propel the boat forward. Propellers are divided into fixed pitch propellers and adjustable pitch propellers.

① Fixed pitch propeller. Consists of a hub and a blade. The propeller blades are generally 3 to 4 pieces. Propeller

The blade near the hub is called the blade root, the outer end is called the blade tip, the front side is called the guide side when running, the rear side is called the follow side, the propeller disc surface towards the stern side is called the discharge side, towards the bow side is called the intake side.

A circular duct is added to the outer edge of the fixed pitch propeller, which is called a duct propeller. The duct can improve the propulsion efficiency of the propeller, but the reversing performance is poor. Conduit propellers can be further divided into fixed and rotatable types. Fixed duct propellers increase the turning diameter of the boat, while rotatable duct propellers improve the turning performance of the boat.

②Adjustable pitch propellers. Through the crank linkage mechanism in the propeller hub, the propeller blade is driven to rotate, and the propulsion power and direction of the propeller can be changed by changing the angle of the blade without changing the speed and direction of the propulsion shaft. Propellers are simple in construction, reliable in operation and highly efficient, and are the main propellers of boats. The propellers of modern boats mostly use large disc ratio, moderate side slope, radial unequal pitch and more blades and other structural forms, in order to reduce the work in the stern of the uneven companion flow field, may produce air bubbles, spalling, noise and excessive vibration force. In some high-speed boats, super vacuolated wing propellers are used. The air propeller used for full cushion lift air cushion traffic boats is similar to the fixed pitch propeller, which uses the reaction force of air to propel the boat forward.

The water jet propeller consists of a water pump, a water suction pipe and a water jet pipe. When moving forward, the water is sucked in by the pump from the suction pipe at the bottom of the boat and sprayed out from the jet pipe at high speed to obtain the reaction force of the water and push the boat forward. When going backwards, the reversing bucket installed above the mouth of the water jet pipe is put into the water, and the high speed water enters the reversing bucket and reflects the water jet to the rear into the water jet to the front, making the boat go backwards without changing the direction of rotation of the main engine. The water jet thruster has good shallow water propulsion efficiency and manoeuvring performance, low noise and vibration, and is a propulsion device used more often in shallow water boats.

Vector thrusters

Broadly speaking, this can refer to all thrusters using thrust vectoring technology, while narrowly speaking, it generally refers to thrust vectoring technology used on aircraft. In short, thrust vectoring is a technique for obtaining additional manoeuvring torque by deflecting the direction of the engine jet. As we know, the thrust acting on an aircraft is a quantity of magnitude and direction, and this quantity is called a vector. However, in a typical aircraft, the thrust is directed forward along the aircraft's axis and the direction cannot be changed, so to emphasise the variable direction of thrust in this technique, we call it thrust vector technology.

In aircraft that do not use thrust vectoring, the engine jets are aligned with the aircraft's axis and the thrust generated is also forward along the axis, in which case the engine thrust is only used to overcome the drag on the aircraft and provide the power to accelerate the aircraft.

Aircraft with thrust vectoring technology, on the other hand, use the thrust generated by the engine, through nozzle deflection, to obtain excess control torque and achieve attitude control of the aircraft. The outstanding feature is that the control torque is closely related to the engine and is not influenced by the aircraft's own attitude. Therefore, it can ensure that the extra manoeuvring torque provided by the thrust vector can be used to control the aircraft manoeuvres when the aircraft is flying at low speed and large angle of attack manoeuvres and the rudder surface is close to failure. Fourth generation fighter aircraft require the ability to manoeuvre over stall, i.e. at large angles of attack. Thrust vectoring technology provides exactly this capability and is a natural choice to achieve the tactical and technical requirements of the fourth generation fighter.

The angle of attack of an ordinary aircraft is relatively small, and in this state the aircraft's wings and tail are able to generate enough lift to ensure normal flight. When the angle of attack gradually increases, the aircraft's tail will be caught in the low-energy wake of the wing, causing the tail to stall and the aircraft to enter a tailspin resulting in a crash. At this point, even if the engine is working properly, it will not be able to keep the aircraft balanced and in the air.

However, when the aircraft is thrust vectored, the engine nozzles are deflected up and down and the resulting thrust no longer passes through the aircraft's centre of gravity, creating a pitch pitch around the aircraft's centre of gravity, where the thrust plays the same role as the aircraft's manoeuvring surfaces. As the thrust is only generated in relation to the engine, even if the aircraft's angle of attack exceeds the stall angle of attack, the thrust can still provide the moment to level the aircraft and the aircraft can continue to fly as long as the wings can still generate enough lift. Furthermore, it has been found that after thrust deflection, not only does the thrust produce direct projected lift, but also induced lift on the wing through the super annular effect, resulting in an increase in total lift.

The thrust vectoring technology has given fighters a huge advantage in the air due to their ability to manoeuvre at overspeed. The US used the thrust vectoring-equipped X-31 demonstrator in a simulated air battle with the F-18, and the X-31 outsold the F-18 by a margin of 1:32.

This is because the supercircular lift and the component of thrust in the direction of lift of an aircraft using thrust vectoring technology help to reduce the aircraft's ground clearance and ground speed, and shorten the glide distance of the aircraft. In addition, because thrust vectoring nozzles can easily be reversed, the aircraft's braking force after landing is also significantly increased, resulting in even shorter landing glide distances.

If the engine nozzle can be deflected not only up and down but also left and right, then the thrust can provide not only the pitch moment but also the yaw moment of the aircraft, making it a fully vectored aircraft.

The use of thrust vectoring technology increases the control efficiency of the aircraft and allows the aerodynamic control surfaces, such as the drogue and vertical tail, to be significantly reduced, thus reducing the weight of the aircraft. In addition, the angular reflector formed by the drogue and vertical tail is thus reduced, and the stealth performance of the aircraft is improved.

Thrust vectoring is a highly integrated technology that includes thrust steering nozzle technology and integrated aircraft airframe/propulsion/control system technology. The development and research of thrust vectoring technology requires cutting-edge aviation technology and reflects a country's comprehensive national strength.

Classification

A propulsion device is a vehicle's propulsion equipment, which converts the power provided by the vehicle's power unit into thrust to propel the vehicle forward.

Depending on the vehicle, there are aero-propulsion, space-propulsion and ship-propulsion.

According to the different principles, there are propeller propellers, air jet propellers, water jet propellers and special propellers.

Among the propeller propellers, there are water propeller propellers and air propeller propellers. Water propellers are used on ships and belong to the category of ship propellers [3]; air propellers are used on aeroplanes and helicopters and belong to the category of aviation propellers.

Common propellers

There are many more types of special propellers, including variable pitch propeller propellers, blade geometry variant propellers, ducted propellers, straight wing propellers, jet propellers, ion propellers, magnetic fluid propellers, superconducting magnetic fluid propellers, etc.

Features

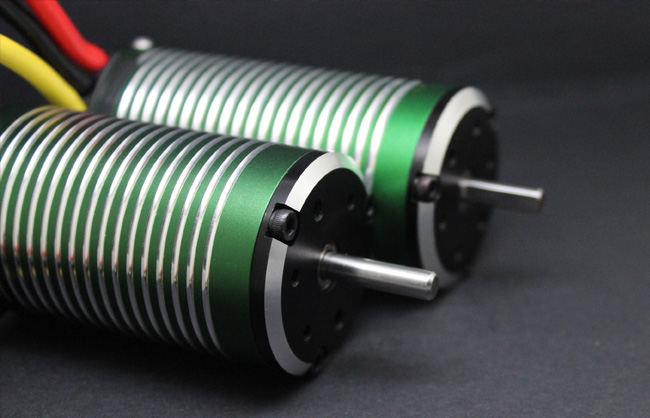

Propellers are more widely used in ships, aviation and other fields, mainly used to propel ships and boats forward, with a wide range of propellers, propeller thrusters, electric marine thrusters, aviation thrusters, water jet thrusters and so on, each of which has its own special uses and characteristics.

Firstly, the propeller has a simple structure and is relatively small in size, occupying a very small area, therefore, it is more flexible in its application and also reflects the concept of green protection.

Secondly, the material of the thruster is generally made of aluminium alloy, which has good corrosion resistance, its corrosion resistance is high, and it can also resist certain underwater impact.

Thirdly, the propeller in the thruster contains three blade-like blades, which rotate at a fast speed and can ensure its working efficiency.

Fourthly, the propeller can also prevent the entanglement of some water plants in the water, which can reduce the occurrence of failures, and the maintenance of the propeller is also relatively easy, as long as you usually pay attention to some can.

Fifth, the use of high-performance motor and battery, improve the efficiency of the machine, but also make it possible to save a certain amount of electricity, its service life is long.

Sixthly, the handle of the pusher is retractable, which is very convenient to use and can also be operated from a distance, and it is also very convenient when it is installed.