INDUSTRY NEWS

Differences and performance comparison between brushless and

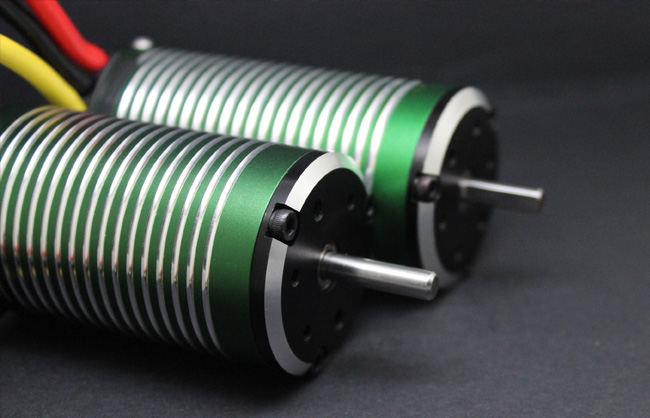

The difference between the two

1, brush motor motor work, the coil and commutator rotation, magnets and carbon brushes do not turn, coil current direction of alternating changes are with the motor rotation of the commutator and brush to complete.

2, brushless DC motor consists of motor body and driver, is a typical mechatronic product. As brushless DC motors operate in a self-controlled manner, they do not add another starting winding to the rotor like synchronous motors that start under heavy load with frequency regulation, nor do they produce oscillations and lost steps when the load changes suddenly.

3, brush motor is a traditional product, the performance is more stable. Brushless motors are upgraded products, and their life performance is better than that of brushed motors. However, its control circuit is more complex, and the ageing screening requirements for components are more stringent.

4. Brushless motor equipment can be used in: dairy industry, brewing industry, meat processing industry, soybean processing industry, beverage processing industry, pastry processing industry, pharmaceutical industry, electronic precision factory, and some higher requirements of the clean room, etc., like the brushless motor (DIHOUR) hand dryer produced by Dio Electric, used in factories more.

5. Carbon brush motors can only be used in various washrooms and other areas where the requirements are not too high, but like clean rooms and explosion-proof workshops can not be used!

6. Service life, brushless motors can work continuously for about 20,000 hours, the conventional service life of 7-10 years. Carbon brush motor: can work continuously for about 5,000 hours, the conventional service life of 2-3 years.

7. Energy saving, relatively speaking, the power consumption of brushless motors is only 1/3 of that of carbon brushes.

A, brushless and brush motor performance comparison

1, friction, loss of some friends in the brush motor often encounter this problem, that is, after using the motor for a period of time, the need to open the motor to clean the motor brush, time-consuming and laborious, maintenance intensity is no less than a family cleaning.

2, heat, short life due to the brush motor structure, brush and commutator contact resistance is very large, resulting in the overall resistance of the motor, easy to heat, and permanent magnets are heat-sensitive components, if the temperature is too high, the magnets will demagnetize, so that the motor performance decreases, affecting the life of the brush motor.

3, low efficiency, small output power above the brush motor heat problem, largely because the current work in the motor internal resistance, so a large degree of electrical energy into heat, so the brush motor output power is not large, efficiency is not high.

Second, the advantages of brushless motor

1, brushless, low interference brushless motor in addition to the brush, the most direct change is that there is no brush motor operation generated by electric sparks, which greatly reduces the interference of electric sparks on remote control radio equipment.

2, low noise, smooth running brushless motor without brushes, friction is greatly reduced when running, smooth running, noise will be much lower, this advantage for the model running stability is a huge support.

3, long life, low maintenance costs less brushes, brushless motor wear is mainly in the bearings, from a mechanical point of view, brushless motor is almost a maintenance-free motor, when necessary, only need to do some dust removal maintenance can be.

Up and down a comparison, you know where the advantages of brushless motor compared to brush motor, but everything is not absolute, brush motor low-speed torque performance, torque and other performance characteristics are irreplaceable brushless motor, but on the brushless motor ease of use, with brushless controller cost down trend and the development of brushless technology at home and abroad and market competition, which also greatly promote the domestic The development of brushless motors.

Third, from the trend, brushless motor deceleration may replace the brush geared motor

1, the scope of application: brushless motor: usually used in the control requirements are relatively high, the speed is relatively high on the equipment, such as models, precision instruments and other strict control of motor speed, speed to reach a very high equipment business, in addition to the most advanced hand dryer, the cost of its motor and controller are very high, so also after the more high-end equipment to be used. Carbon brush motor: usually power equipment used are brushed motors, such as hair dryers, factory motors, household range hoods, etc., in addition to series excitation motor speed can also reach very high, but due to the wear and tear of carbon brushes, service life is not as long as brushless motors.

2, service life brushless motor: usually the service life of tens of thousands of hours in this order of magnitude, but due to the different bearings brushless motor service life is also very different. Carbon brush motor: usually brush motor continuous working life in a few hundred to more than 1,000 hours, to reach the limit of use will need to replace the carbon brush, otherwise it is easy to cause wear and tear of the bearings.

3, the use of effect brushless motor: usually digital frequency control, controllable, from a few revolutions per minute, to tens of thousands of revolutions per minute can be easily achieved. Brushless motors: brushless motors generally work at a constant speed after starting, speed regulation is not very easy, series excitation motors can also reach 20000 rpm, but the service life will be relatively short.

4, energy saving and environmental protection, relatively speaking, brushless motor using frequency conversion technology control will be a lot more energy efficient than series excitation motor, the most typical is the frequency conversion of air conditioners and refrigerators.

5, the future maintenance of carbon brush motors need to replace the carbon brush, if the replacement is not timely will cause damage to the motor, and brushless motor, the service life is very long, usually more than 10 times the brush motor, but the bad need to replace the motor, but the basic routine maintenance does not need.

6, the noise aspect of noise and whether it is brush motor has nothing to do with, mainly depends on the bearing and click the internal components of the cooperation situation.